Green gas

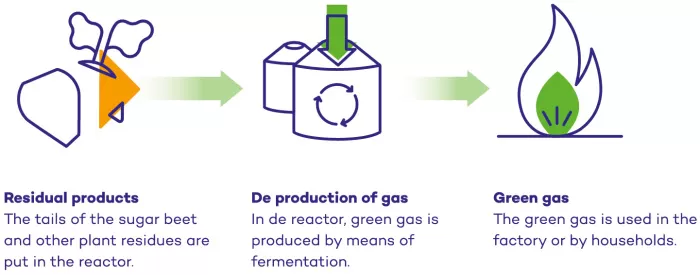

Processing sugar beet produces residual flows, such as beet pulp, beet tips, foliage and molasses. These flows are fermented in biomass digesters to produce energy in the form of biogas. All the valuable minerals remain in the digestate, the feedstock remaining after digestion. The digestate is used to fertilise the farmers’ fields, thus closing a loop in the supply chain. This helps maintain soil health and is a good example of a circular process to close local loops in the supply chain. Each of Cosun Beet Company’s digesters processes more than 100,000 tonnes of biomass every year. This vegetable raw material is sourced mainly from Cosun Beet Company’s own factories.

The sugar factories in Dinteloord and Vierverlaten also operate methane reactors to purify washing water and simultaneously recover biogas.

The biogas is upgraded to green gas. When all the digesters are running at full capacity, Cosun Beet Company feeds more than 25 million cubic metres of green gas into the national gas transmission network, enough for 20,000 households a year. Of the 25 million cubic metres, about 8 million are used instead of natural gas in Cosun Beet Company’s own factories. This cuts their natural gas consumption by about 10% a year. Cosun Beet Company is one of the biggest producers of green gas in the Netherlands.

Wind energy

There are four wind turbines on the Cosun Beet Company site in Dinteloord. These wind turbines are the property of Pure Energy, which also operates them. The turbines generate more than 31,000,000 kWh of sustainable energy every year, all of which is supplied to the public grid. This is comparable to the annual consumption of more than 10,000 households. It also covers the electrical energy used at Cosun Beet Company’s head office. Click here for more information (only available in Dutch).

Solar energy

Cosun Beet Company wants to use as much sustainable energy as possible. The sugar specialities factories in Puttershoek en Roosendaal are now the first two plants to cover their electricity consumption with solar power. In the summer of 2021 Cosun Beet Company realized a solar park of 17 ha on an old industrial site in Puttershoek. Of these 17 ha, 7 ha (equivalent to 9,7 MW peak power) have been connected directly to the sugar specialities factory in Puttershoek. The electricity produced by these 7 ha is overall enough for both sugar specialities factories. However, both factories remain connected to the national electricity grid, because in summer these 7 ha produce too much and in winter too little electricity to cover daily demand. The remaining 10 ha of the solar park are owned by Klimaat Fonds Nederland. These are connected directly to the national electricity grid. Klimaatfonds Nederland invests in the production of renewable energy.

While other players in the European sugar industry are only now switching from coal to gas, Cosun Beet Company is already taking the next step in the energy transition: from natural gas to green gas and solar power.

Bio-ethanol

The sugar beet factories produce not only white sugar but also bio-ethanol, biomethane and animal feed. Bio-ethanol and biomethane are sustainable alternatives to fossil fuels and are used in the chemical industry.

Bio-ethanol developments at our factory in Anklam, Germany:

- Start of production in Anklam in 2008

- Bio-ethanol is produced from thin juice during the beet campaign and thick juice

- Bio-ethanol is used to produce biofuels and in the chemical industry

- 100% certification under the Biofuel Sustainability Ordinance

- The factory is certified to ISO 14001, ISO 50001, ISO 22000, etc.